Discovering the Important Features and Advantages of Steel Factories

Metal foundries serve an essential function in the production landscape. They change resources into exact metal items for various markets. This procedure entails specialized techniques that guarantee quality and efficiency. The financial implications are considerable, affecting neighborhood neighborhoods and task markets. As innovation progresses, so do the techniques within the sector. Recognizing these characteristics discloses much concerning the future of production and its function in sustainability. What exists ahead for steel shops?

The Role of Metal Shops in Manufacturing

Steel factories play an important role in the manufacturing sector by changing resources right into useful metal items. These facilities focus on melting and spreading steels, utilizing a variety of methods to produce elements that serve multiple sectors, consisting of vehicle, aerospace, and building and construction. By transforming raw metal ores, scrap metal, and alloys right into precise sizes and shapes, shops make it possible for producers to create premium products tailored to specific applications.

Additionally, metal shops contribute significantly to the economic climate by cultivating and supplying work advancement in metalworking technologies. They commonly purchase r & d to improve effectiveness and sustainability, reducing waste and energy intake throughout manufacturing processes. The capacity to generate complex geometries not just fulfills design demands but likewise enhances general item performance. Essentially, steel shops work as a vital link in the supply chain, making certain the accessibility of crucial steel components for a myriad of applications in contemporary production.

Essential Procedures Involved in Steel Casting

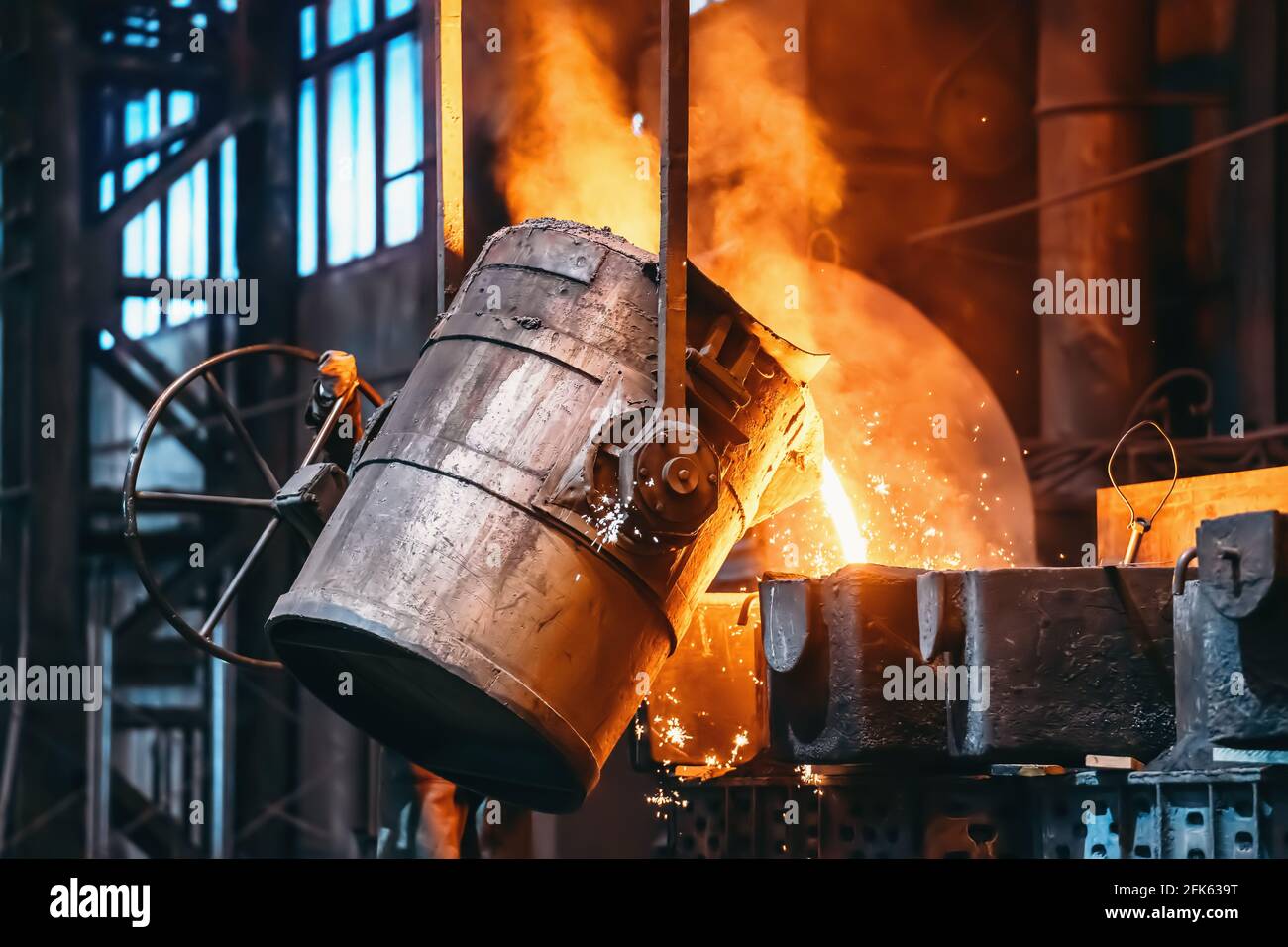

In the process of changing basic materials right into completed products, steel casting incorporates a number of key treatments that safeguard the manufacturing of high-quality parts. Originally, the procedure begins with the prep work of liquified steel, which typically includes melting resources in a heater. As soon as the steel gets to the preferred temperature, it is put into a mold shaped to form the final product.

Air conditioning adheres to, where the molten metal strengthens within the mold and mildew, handling its brand-new shape. After sufficient air conditioning, the mold and mildew is gotten rid of, disclosing the cast part. This is often complied with by ending up procedures, including machining, to accomplish accurate dimensions and surface area top quality. Furthermore, inspections are carried out to identify that the spreadings satisfy defined resistances and criteria. These essential processes highlight the complex nature of steel casting, emphasizing the critical function that each step plays in generating long lasting and dependable steel items.

Kinds Of Metals Typically Made Use Of in Shops

While various metals can be made use of in factories, a number of stand apart due to their distinct residential properties and suitability for specific applications. Iron, particularly in the form of actors iron, is renowned for its stamina, sturdiness, and outstanding spreading attributes, making it optimal for equipment and automobile components. Light weight aluminum is favored for its lightweight nature and resistance to corrosion, frequently used in aerospace and transport fields. Copper alloys, such as bronze and brass, are picked for their extraordinary conductivity and visual appeal, generally found in electric parts and attractive items. Steel, particularly carbon steel, is valued for its strength and adaptability, widely used in building and manufacturing. Magnesium is appreciated for its low thickness and high strength-to-weight ratio, making it a recommended selection in applications requiring lightweight materials. Each of these metals uses unique benefits that satisfy the varied requirements of numerous sectors.

High Quality Control Actions in Metal Shops

Quality control steps in metal shops are crucial for making sure product honesty and conformity with industry standards (Metal Foundry). Various evaluation methods are utilized to examine the residential or commercial properties of actors metals, while adherence to established qualifications and requirements strengthens top quality guarantee. This methodical method not only enhances functional performance but likewise develops consumer count on the final products

Assessment Techniques Overview

Effective inspection strategies are vital for keeping high requirements in metal factories, as they guarantee that each item meets specified resistances and performance requirements. Numerous approaches are used to analyze the top quality of spreadings, consisting of visual examinations, dimensional checks, and non-destructive screening (NDT) Aesthetic examinations allow drivers to determine surface area problems such as inclusions or fractures, while dimensional checks confirm that parts adhere to develop requirements. NDT strategies, such as ultrasonic and radiographic screening, give deeper insights right into inner problems without harming the item. Furthermore, computerized inspection systems are significantly made use of to enhance precision and efficiency. Together, these assessment strategies play a significant duty in safeguarding item reliability and consumer satisfaction within the competitive landscape of steel shops.

Criteria and Certifications

In the domain of metal factories, adherence to established accreditations and criteria offers as a keystone for he has a good point top quality control measures. These requirements, such as ISO 9001 and ASTM, give frameworks that guarantee consistent item quality and dependability. Qualification procedures involve rigorous assessments, consisting of audits and assessments, confirming that shops satisfy certain performance requirements. Compliance with these standards not only boosts item honesty but likewise promotes client depend on and satisfaction. Additionally, qualification can open up brand-new markets, as several markets need compliance for purchase. By executing these quality assurance steps, steel factories can reduce problems, enhance production procedures, and preserve an one-upmanship in the market. Generally, requirements and accreditations play an essential function in assuring the success and sustainability of metal foundries.

Advancements and Technologies in Shop Operations

As the need for precision and efficiency in metal casting remains to expand, shops are progressively taking on technologies and technologies that enhance their operations. Automation plays a critical role, with robotic systems enhancing procedures such as mold and mildew handling and spreading. This not only decreases labor expenses however additionally decreases human error, leading to enhanced item quality.

Furthermore, advancements in computer-aided layout (CAD) and simulation software application enable shops to enhance layouts before production, permitting for faster turnaround times. Incorporating 3D printing innovation for developing molds and cores better accelerates manufacturing and enables for complicated geometries that conventional approaches can not attain.

The assimilation of data analytics and the Web of Points (IoT) provides real-time monitoring of devices and procedures, improving anticipating upkeep and functional performance. These developments collectively add to a much more receptive, active, and affordable factory environment, placing them well to satisfy progressing market demands.

Financial Impact of Steel Shops on Local Communities

The developments in innovation within metal factories not just improve production capacities however also significantly affect regional economies. Metal foundries work as a considerable source of employment, offering jobs for knowledgeable employees and adding to the financial security of their regions (Aluminum Foundry). These facilities often stimulate neighborhood businesses, as they call for a variety of products and solutions, from basic materials to transportation and logistics. The presence of a steel shop can also bring in related industries, fostering a network of distributors and sustaining companies that thrive in distance to making centers

Shops contribute to the tax obligation base, creating revenue for regional federal governments that can be used for public services and infrastructure improvements. The financial ripple result includes community growth, as factories usually participate in local efforts and assistance workforce training click here now programs. Overall, metal foundries play a crucial duty in reinforcing the financial landscape of their communities, making certain growth and sustainability.

Sustainability Practices in the Steel Factory Market

The metal foundry sector is progressively embracing sustainability methods to decrease its ecological footprint. Key strategies include recycling metal scrap, applying energy effectiveness procedures, and utilizing green spreading procedures. These efforts not just contribute to source preservation yet also improve the industry's overall sustainability account.

Recycling Steel Scrap

Recycling steel scrap stands as a foundation of sustainability practices within the steel shop sector. This process not just conserves natural deposits but also substantially reduces land fill waste. By recovering scrap steel, factories can minimize the need for virgin products, reducing environmental effect and energy usage connected with mining and removal. The recycling of steel scrap cultivates a circular economic climate, where products are reused and repurposed, click for more info producing a more sustainable production cycle. Shops typically carry out innovative sorting and processing modern technologies to boost reusing efficiency, making sure top notch result. As the sector significantly prioritizes eco-friendly techniques, the recycling of steel scrap remains an important component, advertising both economic viability and ecological stewardship for future generations.

Power Effectiveness Actions

Sustainability in the steel shop market extends past reusing methods to include power effectiveness steps. Shops are progressively embracing innovations that decrease energy intake throughout metal production and spreading. Implementing advanced melting techniques, such as induction melting, enables even more specific temperature control and minimized power waste. In addition, optimizing heater operations via heat healing systems records and reuses excess warmth, especially reducing overall energy requirements. The assimilation of energy-efficient lights and automation additionally improves operational effectiveness. By buying these power performance actions, foundries not just decrease their carbon footprint however also recognize expense financial savings, adding to an extra economically practical and lasting sector. Adopting such practices is essential for dealing with and meeting regulatory requirements growing ecological concerns.

Eco-Friendly Casting Processes

While traditional spreading techniques have offered the metal shop market for decades, environmentally friendly spreading processes are now obtaining importance as a crucial element of lasting manufacturing. These cutting-edge methods focus on the reduction of waste, energy consumption, and damaging discharges. Lots of factories are taking on recyclable products and water-based layers, decreasing ecological effect. Furthermore, improvements in 3D printing innovation help with much more efficient layouts, minimizing the requirement for substantial material use. Closed-loop systems are additionally being carried out, permitting the recycling of metals and other by-products. By accepting these eco-friendly practices, metal foundries not just improve their operational performance however likewise contribute to the international effort toward sustainability, straightening with enhancing customer demand for eco liable items.

Regularly Asked Inquiries

What Security Actions Are Implemented in Steel Foundries?

Safety steps in metal factories include personal safety equipment, proper ventilation systems, normal security training, threat communication, emergency reaction procedures, and regular devices upkeep to lessen threats related to high temperatures and harmful products.

Just How Do Shops Take Care Of Hazardous Products?

What Are Common Career Opportunities in Metal Foundries?

Common job opportunities in metal foundries include functions such as factory professional, melting operator, quality assurance examiner, maintenance engineer, and manufacturing supervisor, each adding to the effective operation and result of steel casting procedures.

How Do Foundries Take Care Of Waste and Recycling?

Foundries take care of waste and reusing with organized processes, including the collection of scrap metal, reusing materials, and executing eco-friendly practices (Metal Casting). These techniques help lessen environmental influence while promoting source efficiency within the industry

What Are the Ecological Rules for Metal Foundries?

Metal shops play a vital function in the production market by transforming raw products into useful metal items. Quality control steps in steel factories are essential for ensuring item stability and compliance with sector standards. By implementing these high quality control steps, metal factories can minimize issues, enhance manufacturing procedures, and maintain an affordable side in the industry. Reusing steel scrap stands as a foundation of sustainability practices within the steel shop industry. While typical casting techniques have actually offered the metal shop sector for years, eco-friendly spreading procedures are currently getting prominence as an essential element of lasting manufacturing.